The no-leakage fluorine-lined magnetic pump is characterized by its high corrosion resistance, which is attributed to the fluorine lining. The magnetic drive mechanism ensures a hermetic seal, preventing any leakage, and making it suitable for a wide range of fluid transfer applications.

Pago:

TT L/C PayPal Westunion MoneygramOrigen del producto:

China, Anhui provinceColor:

customizedPuerto de envío:

shanghaiTiempo de entrega:

1 monthMoq:

1Paquete:

CustomizedColor:

CustomizedMaterial:

HT200 lined F46Temperatura de trabajo:

-20 to 120°C; -20 to 80°C.Presión de trabajo:

1.6 MPa

Product overview

The TCF leakage-free fluorine-lined magnetic pump represents a novel type of magnetic pump. It operates based on the principles of modern magnetomechanics and utilizes the magnetic transmission capabilities of permanent magnets to achieve non-contact torque transmission. All the parts that come into contact with the fluid (overflow parts) are crafted from fluoroplastic. This enables the pump to handle and transport corrosive media, including acids, alkalis, and oxidants, regardless of their concentration (strength).

Product advantages

1. The pump body is constructed using cast iron, carbon steel, 304, or 316L, with a lining of fluoroplastics. Meanwhile, the inner rotor, pump cover, impeller, isolation sleeve, and other components that come into contact with the fluid (overflow parts) are fabricated with metal inserts that are encapsulated in fluoroplastics.

2. The magnet employed is a novel type of permanent magnet, which exhibits excellent magnetic properties, high temperature resistance, and no demagnetization.

3. The shaft sleeve and sliding bearing are made from highly wear-resistant materials such as silicon carbide, graphite, and tetrafluoro. Additionally, they are equipped with lubrication grooves, which effectively ensure the service life of the pump. The seal utilized is a closed static seal, which completely resolves the issue of medium leakage. Moreover, it eliminates the necessity for independent lubrication and cooling water, thereby reducing energy consumption.

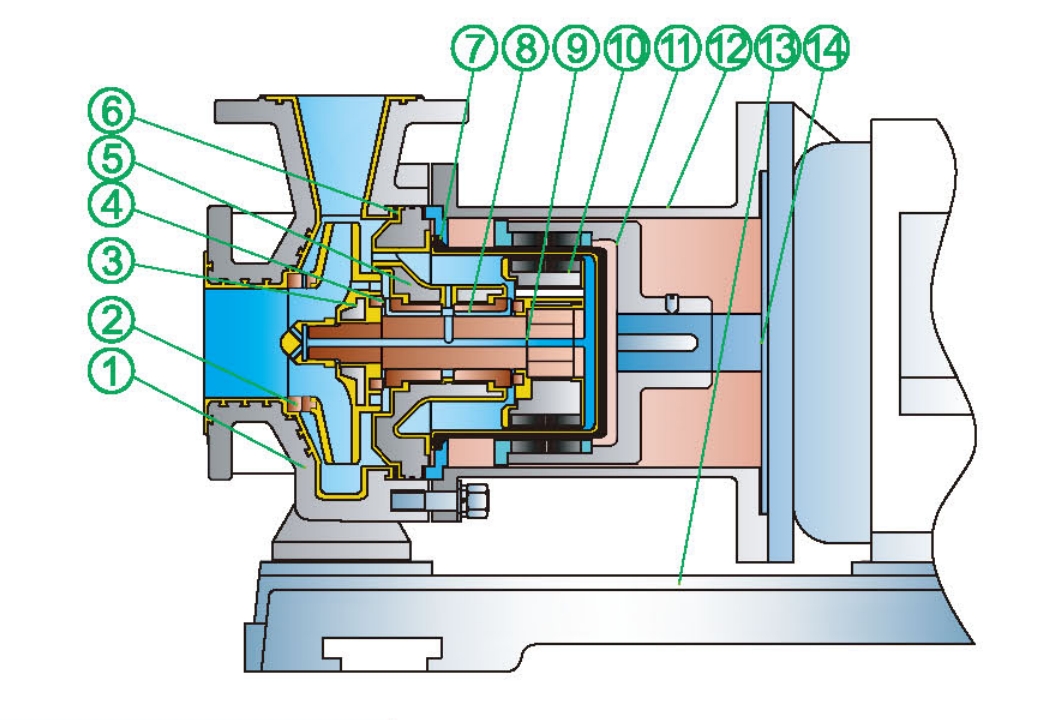

Material List

| Part | Material | Part | Material | Part | Material |

| ①Pump body | HT200 lined F46 | ⑤Axle sleeve | Impregnated graphite/SIC | ⑨Rear nut | Tetrafluoro |

| ②impeller nut | HT200 lined F46 | ⑥Pump cover | HT200 lined F46 | ⑩External magnetic | Permanent magnetic/HT200 lined F46 |

| ③impeller | F50 | ⑦Spacer sleeve | PEEK/F46 | ⑪ Connecting frame | HT200 |

| ④shaft | SIC | ⑧Internal magnetic | Permenant magnetic/HT200 lined F46 | ⑫ Electric motor | Customized |

Structural diagram

Performance Data

| Type | Rated power | Rated flow | Rated head | Voltage | Pump casing material | Suction |

| 40-25-125 | 2.2 | 6.3 | 20 | 380V | HT200 lined F46 | 40*25 |

| 40-25-160 | 3 | 6.3 | 32 | 380V | HT200 lined F46 | 40*25 |

| 40-25-200 | 5.5 | 6.3 | 50 | 380V | HT200 lined F46 | 40*25 |

| 40-25-250 | 11 | 6.3 | 80 | 380V | HT200 lined F46 | 40*25 |

| 40-25-315 | 6.3 | 125 | 380V | HT200 lined F46 | 40*25 | |

| 50-32-125 | 2.2 | 12.5 | 20 | 380V | HT200 lined F46 | 50*32 |

| 50-32-160 | 4 | 12.5 | 32 | 380V | HT200 lined F46 | 50*32 |

| 50-32-200 | 7.5 | 12.5 | 50 | 380V | HT200 lined F46 | 50*32 |

| 50-32-250 | 15 | 12.5 | 80 | 380V | HT200 lined F46 | 50*32 |

| 50-32-315 | 12.5 | 125 | 380V | HT200 lined F46 | 50*32 | |

| 65-50-125 | 4 | 25 | 20 | 380V | HT200 lined F46 | 65*50 |

| 65-50-160 | 5.5 | 25 | 32 | 380V | HT200 lined F46 | 65*50 |

| 65-40-200 | 11 | 25 | 50 | 380V | HT200 lined F46 | 65*40 |

| 65-40-250 | 18.5 | 25 | 80 | 380V | HT200 lined F46 | 65*40 |

| 65-40-315 | 37 | 25 | 125 | 380V | HT200 lined F46 | 65*40 |

| 80-65-125 | 7.5 | 50 | 20 | 380V | HT200 lined F46 | 80*65 |

| 80-65-160 | 11 | 50 | 32 | 380V | HT200 lined F46 | 80*65 |

| 80-50-200 | 18.5 | 50 | 50 | 380V | HT200 lined F46 | 80*50 |

| 80-50-250 | 30 | 50 | 80 | 380V | HT200 lined F46 | 80*50 |

| 80-50-315 | 55 | 50 | 125 | 380V | HT200 lined F46 | 80*50 |

| 100-80-125 | 11 | 100 | 20 | 380V | HT200 lined F46 | 100*80 |

| 100-80-160 | 18.5 | 100 | 32 | 380V | HT200 lined F46 | 100*80 |

| 100-65-200 | 30 | 100 | 50 | 380V | HT200 lined F46 | 100*65 |

| 100-65-250 | 45 | 100 | 80 | 380V | HT200 lined F46 | 100*65 |

| 100-65-315 | 75 | 100 | 125 | 380V | HT200 lined F46 | 100*65 |

| 125-80-160 | 30 | 160 | 32 | 380V | HT200 lined F46 | 125*80 |

| 125-100-200 | 55 | 100 | 50 | 380V | HT200 lined F46 | 125*100 |

| 125-100-250 | 75 | 100 | 80 | 380V | HT200 lined F46 | 125*100 |

| 125-100-315 | 22 | 100 | 125 | 380V | HT200 lined F46 | 125*100 |

| 125-100-400 | 37 | 100 | 50 | 380V | HT200 lined F46 | 150*125 |

| 150-125-250 | 22 | 200 | 20 | 380V | HT200 lined F46 | 150*125 |

| 150-125-315 | 45 | 200 | 32 | 380V | HT200 lined F46 | 150*125 |

| 150-125-400 | 55 | 200 | 50 | 380V | HT200 lined F46 | 150*125 |

| 200-150-250 | 55 | 400 | 20 | 380V | HT200 lined F46 | 200*150 |

| 200-150-315 | 75 | 400 | 32 | 380V | HT200 lined F46 | 200*150 |

| 200-150-400 | 110 | 400 | 50 | 380V | HT200 lined F46 | 200*150 |

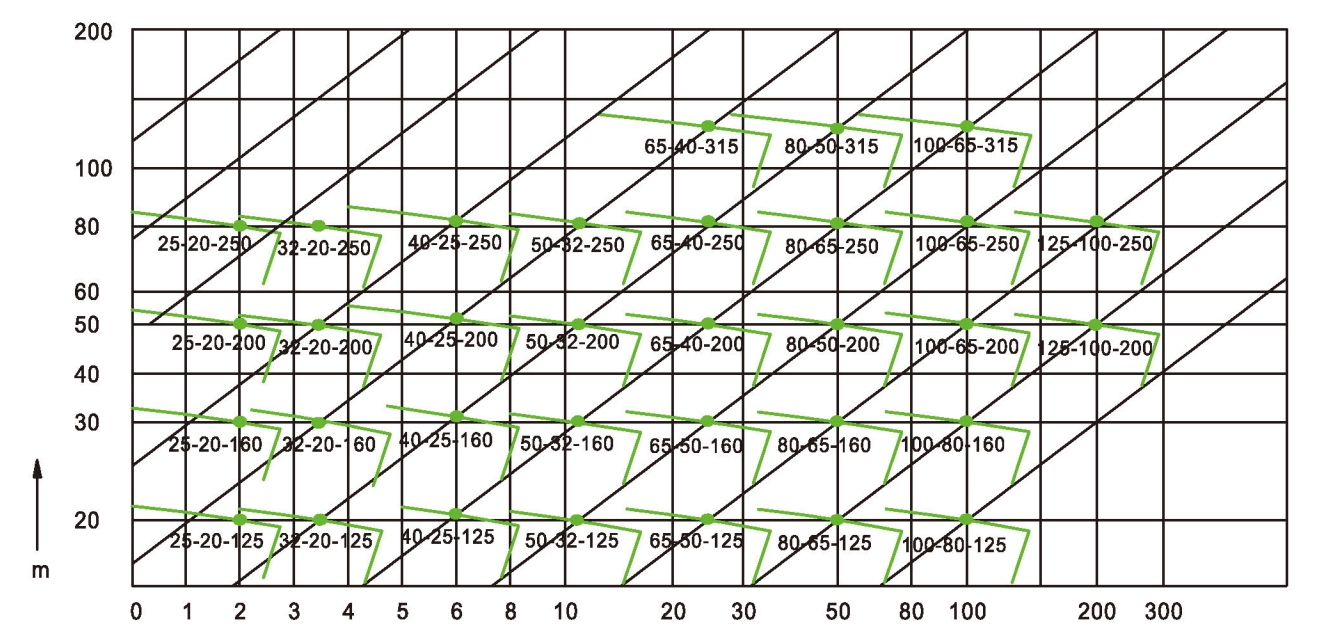

Performance range

Design pressure: 1.6 MPa, Flow: 0.5~240 m³/h, Head: 20~125 m, Power: 1.1~55 KW.

Applicable temperature: ①Fluoroplastic material acid-base medium of any concentration -20~120°C;

②Engineering plastic material, dilute acid and alkali medium -20~80°C.

Product application

It finds extensive application in the transportation of corrosive liquids within the production processes of various industries, including petroleum, chemical engineering, acid production, alkali production, smelting, rare earth extraction, pesticide manufacturing, dye production, pharmaceuticals, papermaking, electroplating, electrolysis, and pickling. It is particularly suitable for transporting flammable, explosive, volatile, toxic, strong acid-base, organic agents, and precious liquids.

Others