The Block-hole Three-in-one Hydrochloric Acid Synthesis Furnace integrates the functions of reaction, heat exchange, and product treatment. It is highly efficient and stable in the production of HCl, enabling energy savings and ensuring operational safety.

Pago:

TT L/C PayPal Westunion MoneygramPuerto de envío:

shanghaiTiempo de entrega:

1 monthMoq:

1Paquete:

wooden caseColor:

whiteMaterial:

graphite stainless steelTemperatura de trabajo:

graphite wall≤170℃ acid producing ≤45℃

Product review

This equipment features a compact structure and a small footprint. It offers high production efficiency, producing product acid with a high degree of purity. Moreover, it is easy to control, demonstrating a high comprehensive volume efficiency in synthesis, absorption, and cooling processes, along with a high absorption intensity.

It has the capacity to significantly enhance production capabilities while simplifying the production process. Overall, it is a type of hydrochloric acid production equipment that is characterized by high strength and high efficiency.

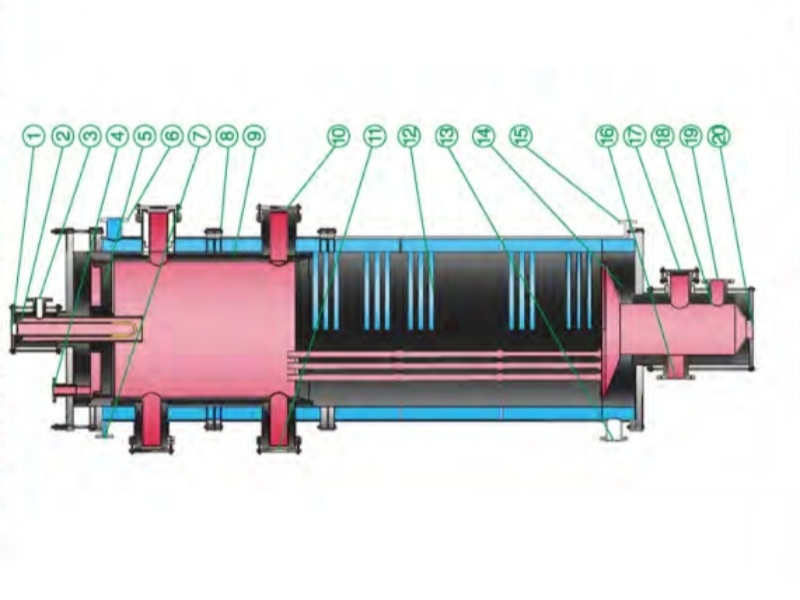

1. Block Hole Structure

The furnace might incorporate a distinctive block hole design. This block hole structure plays a crucial role in evenly dispersing the reactant gases throughout the furnace. Take the synthesis of hydrochloric acid from hydrogen and chlorine as an example. The block hole design enables these two gases to interact thoroughly, thereby expanding the effective reaction area and enhancing the reaction efficiency.

The dimensions, shape, and layout of the block holes are meticulously engineered. Suitably sized block holes are essential as they prevent the blockage of reactants or products within the furnace, thus ensuring the seamless continuation of the reaction process.

2. Three-in-one Functional Integration

The concept of "three-in-one" typically involves the integration of multiple functions. For instance, it could combine functions such as facilitating the reaction, enabling heat exchange, and performing preliminary product treatment within a single furnace body.

During the acid synthesis process, the reaction is frequently accompanied by either the release or absorption of heat. The three-in-one design allows for efficient heat transfer within the furnace. For example, through specialized heat exchange pipes or jacket structures, it can maintain the specific temperature conditions necessary for the reaction, while simultaneously preventing any local overheating or overcooling that could potentially disrupt the reaction process.

Parts Details

| 1 | Chlorine inlet | 11 | Mirror port |

| 2 | lamp holder | 12 | absorbs fast |

| 3 | Hydrogen inlet | 13 | Cooling outlet |

| 4 | acid inlet | 14 | lower head |

| 5 | upper head | 15 | Drain port |

| 6 | water outlet | 16 | gas port |

| 7 | Vent | 17 | water inlet |

| 8 | Mirror | 18 | liquid separator |

| 9 | synthesis section | 19 | discharge inlet |

| 10 | membrane port | 20 | Acid outlet |

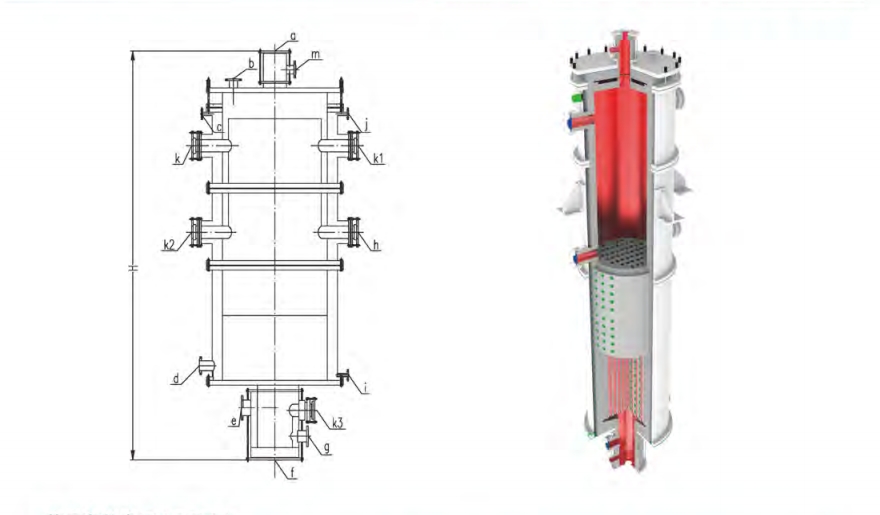

Specification

| YKSL-30 | YKSL-30 | YKSL-40 | YKSL-40 | YKSL-50 | YKSL-50 | YKSL-60 | YKSL-60 | |

| Nominal diameter | Connec- tion size | Nominal diameter | Connec- tion size | Nominal diameter | Connec- tion size | Nominal diameter | Connec- tion size | |

| a.b | 40 | 80 | 60 | 100 | 75 | 125 | 90 | 150 |

| c.i | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| d | 80 | 80 | 80 | 80 | 100 | 100 | 100 | 100 |

| e.f | 100 | 150 | 100 | 150 | 125 | 200 | 125 | 175 |

| g | 75 | 100 | 75 | 100 | 75 | 100 | 75 | 100 |

| j | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 |

| m | 40 | 80 | 60 | 100 | 75 | 125 | 90 | 150 |

| DN | 300 | 300 | 400 | 400 | 500 | 500 | 600 | 600 |

| H | 7480 | 7480 | 7510 | 7510 | 7580 | 7580 | 7660 | 7660 |

| Output | 10-20 | 10-20 | 20-30 | 20-30 | 30-40 | 30-40 | 40-50 | 40-50 |

| YKSL-70 | YKSL-70 | YKSL-80 | YKSL-80 | YKSL-90 | YKSL-90 | YKSL-100 | YKSL-100 | |

| Nominal diameter | Connec- tion size | Nominal diameter | Connec- tion size | Nominal diameter | Connec- tion size | Nominal diameter | Connec- tion size | |

| a.b | 90 | 150 | 120 | 200 | 135 | 200 | 150 | 200 |

| c.i | 25 | 250 | 25 | 25 | 25 | 25 | 25 | 25 |

| d | 100 | 100 | 125 | 125 | 125 | 125 | 125 | 125 |

| e.f | 150 | 200 | 150 | 250 | 200 | 250 | 200 | 200 |

| g | 75 | 100 | 75 | 100 | 75 | 100 | 75 | 100 |

| j | 125 | 125 | 150 | 150 | 150 | 150 | 150 | 150 |

| m | 90 | 150 | 120 | 200 | 135 | 200 | 150 | 150 |

| DN | 700 | 700 | 800 | 800 | 900 | 900 | 100 | 100 |

| H | 7660 | 7660 | 7710 | 7710 | 7760 | 7760 | 7760 | 7760 |

| Output | 50-60 | 50-60 | 60-70 | 60-70 | 70-80 | 70-80 | 80-90 | 80-90 |

Others